AiCROV is the most innovative and dynamic company in the design, manufacture, maintenance, and improvement of liquid filling systems for large-format containers. Their systems handle containers from 1 liter up to 1,500 liters, achieving productivities of up to 1,000 containers per hour with a precision of up to 5 grams.

Challenge: The main challenge for the company was to solve the problems that 2D vision caused in their machines. Another major challenge was the standardization of the solution for the Advanced series of their filling machines. Ultimately, they were seeking a new solution that would improve production efficiency, filling quality, and, of course, customer satisfaction. Until then, 2D vision systems required containers to be perfectly positioned on the pallet, with their tops perfectly horizontal. Each degree of tilt caused errors in calculating the rim positions, directly proportional to the imperfections of the containers.

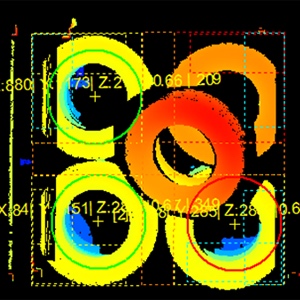

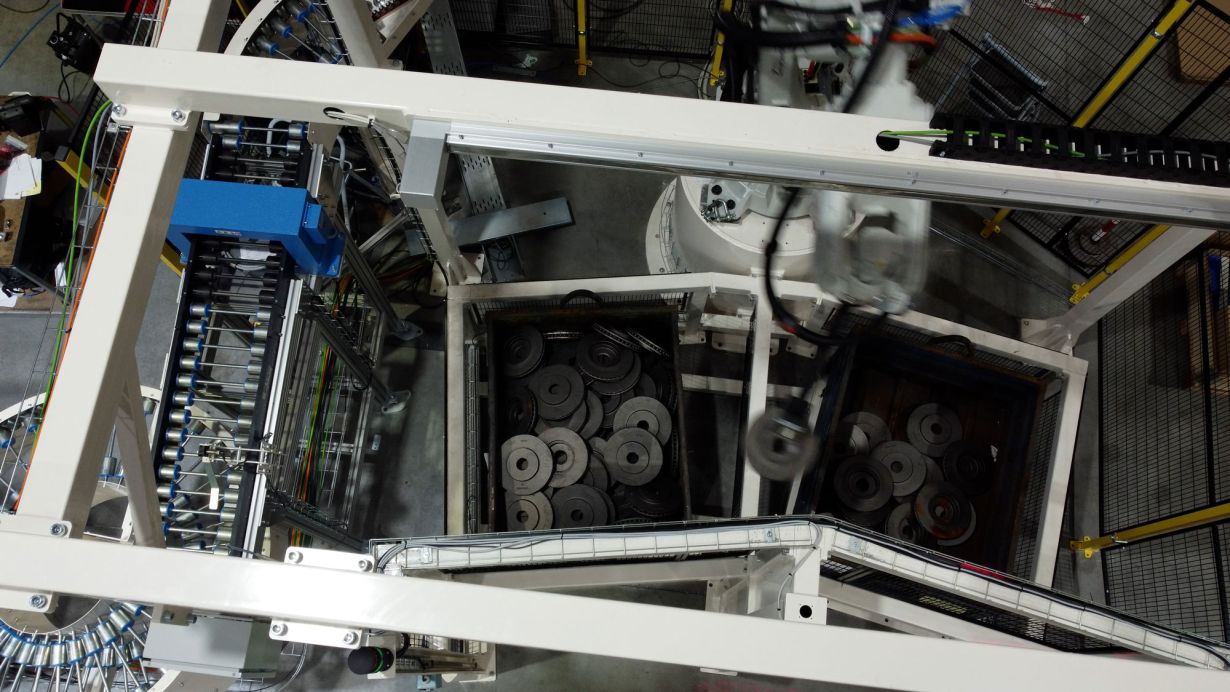

Solution: The solution is a fully automated machine for line production filling and weighing of drums, cans, barrels, and IBCs on pallets. A Photoneo 3D scanner scans the container surfaces, creating a point cloud 3D model that allows precise determination of hole position, height, and horizontal tilt. Calibration between the scanner and the robot provides the X, Y, Z coordinates so the robot can perform its tasks accurately. This application operates in an explosion-proof environment for hazardous areas, with the Photoneo laser fully covered, as shown in the video. With the new 3D technology, optical errors are minimized, significantly increasing machine efficiency, especially with plastic containers, which often deform during manufacturing. This allows filling times to be reduced by half. The improved calculation of hole positions translates directly into greater process reliability, minimizing machine stoppages due to misalignment between the hole and the machine.

3D Vision System Functions:

- Detection of holes in containers.

- Detection of containers with or without lids.

- Orientation for the robot to correctly position the rims.

- Guidance for the robot to screw and unscrew lids.

- Detection of cap tilt.

All this works with different types of containers and drums, various hole diameters, and different types of screws (internal and external), both inside and outside EX zones.

Using Photoneo in their filling systems allows AiCROV to reduce production costs, increase productivity, and meet the highest safety and quality standards.

Advantages of the 3D System:

- Absorbs variations in height.

- Works regardless of color or low contrast.

- No need for perfectly positioned containers.